Airport facilities in La Tuque

Airport facilities in La Tuque

2024

Airport

The gbi team was commissioned by the City of La Tuque to rehabilitate the La Tuque Airport runway in the fields of civil, electrical, and transportation engineering. This project addresses the growing challenges of modern aviation and the runway safety issues arising from the pavement’s poor condition.

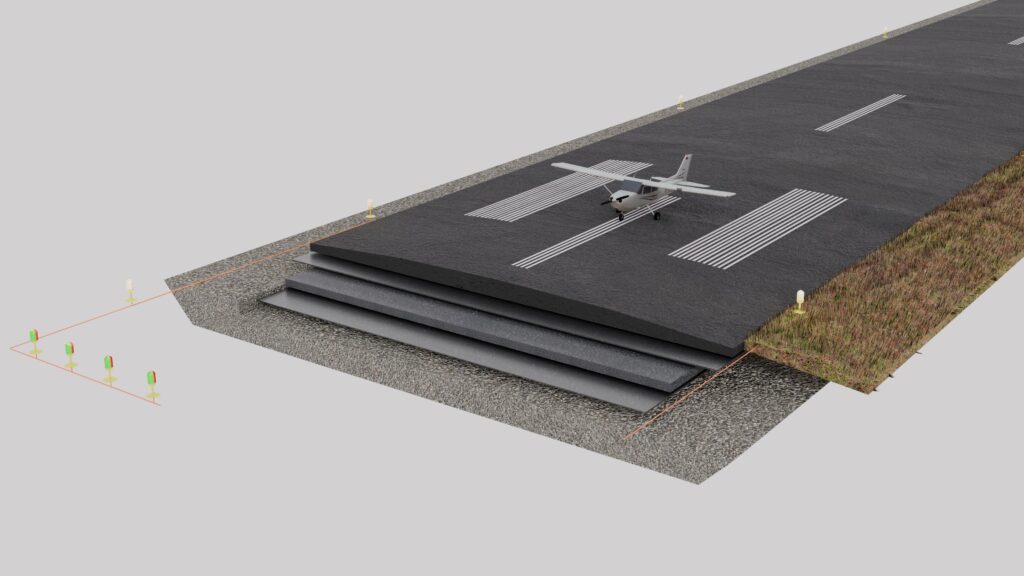

The team developed an ingenious choice of materials by removing the pavement and 100 millimeters of sand, then combining a stone amendment mixed with the existing soil. This idea came from a collaboration with Eurovia, a partner in the materials sector. Together, they determined the optimal gradation for the stone and sand mixture, ensuring maximum adhesion, unmatched flexibility, and exceptional resistance to environmental and thermal stresses.

A strategic plan was incorporated into the project to allow for a potential 1,000-foot runway extension at the client’s request. Load calculations and electrical forecasts were carefully considered to support this possible expansion. The electrical infrastructure, including the cables, has already been prepared to seamlessly adapt to future requirements.

Designed to Meet Complex Challenges

The complexity of this project lies primarily in its ability to adapt to major thermal constraints and inherent ground movements. The load-bearing capacity must remain flawless despite the natural drainage, which is unusual for this type of project.

While most traditional runways integrate drains and catch basins, this is not the case for the La Tuque airport due to the soil composition. The runway must therefore be naturally draining, despite extreme weather conditions. It is therefore imperative that the soil gradation be suitable to allow water to flow and ensure runway safety.

tonnes of materials reused

truck trips avoided

square metres of runway surface

Runway Adaptation

The airport’s terrain and weather conditions were at the heart of the challenge. Located in a zone subject to major thermal constraints, temperature variations range from extremely high in summer to frigid in winter, causing significant ground movement and material expansion. The runway, in service for over 50 years, was also built on a sand base with no drainage system.

Pavement Composition

The subgrade composition of the old runway exceeded acceptable gradation standards (11% of the mix corresponding to 80 microns), which led gbi to propose an alternative solution for the pavement structure. Pulverizing the existing asphalt and mixing it with the existing soil would have had a negative impact on the runway’s durability due to ground movement resulting from the lack of drainage.

Sample testing was carried out and achieved a 98% success rate across 10 soil samples from the new runway. The bearing capacity solutions implemented now allow the airport to accommodate larger aircraft.

Material Reuse

From an economic perspective, the drastic reduction in material transportation needs, resulting from the ingenious reuse of on-site resources, led to significant cost savings. This logistical efficiency also avoided moving 16,000 tonnes of materials, equivalent to 1,100 truck trips on the roads of the City of La Tuque, trips that would have increased regional traffic congestion and impacted residents’ daily lives. This reuse strategy saved the client nearly half a million dollars in transportation costs alone, while also benefiting the environment.

A Standout Project

The La Tuque Airport facilities rehabilitation project was a finalist at the 2024 Grands Prix du génie-conseil québécois in the Transportation Infrastructure category of the Association des firmes de génie-conseil Québec.

It was also a finalist at the 2024 Grands Prix d’excellence of the Association québécoise des transports.

This project was very important because our airport is an essential asset for our community. We had to take action to make it safer and more attractive. We are very proud of its completion, as it was carried out in a spirit of collaboration between the City, its consulting expert, and the contractor at every stage. The schedule was respected, which was crucial to minimize the impact on our operations.

Luc Martel

Mayor of La Tuque