Clé-des-Champs School

Clé-des-Champs School

2022

Educational

Canadian Consulting Engineering Awards

2023

Canadian Consulting Engineering Awards

2023

Grands Prix du génie-conseil québécois

2023

ASHRAE Region 2 Technologies Award

2024

Ordre des ingénieurs du Québec

2024

The Clé-des-Champs School project, under the Mille-Îles School Service Centre, is the first institutional building in Canada to integrate permanent column wells (PCWs). It represents a direct response to the desire to make a major shift in energy consumption practices.

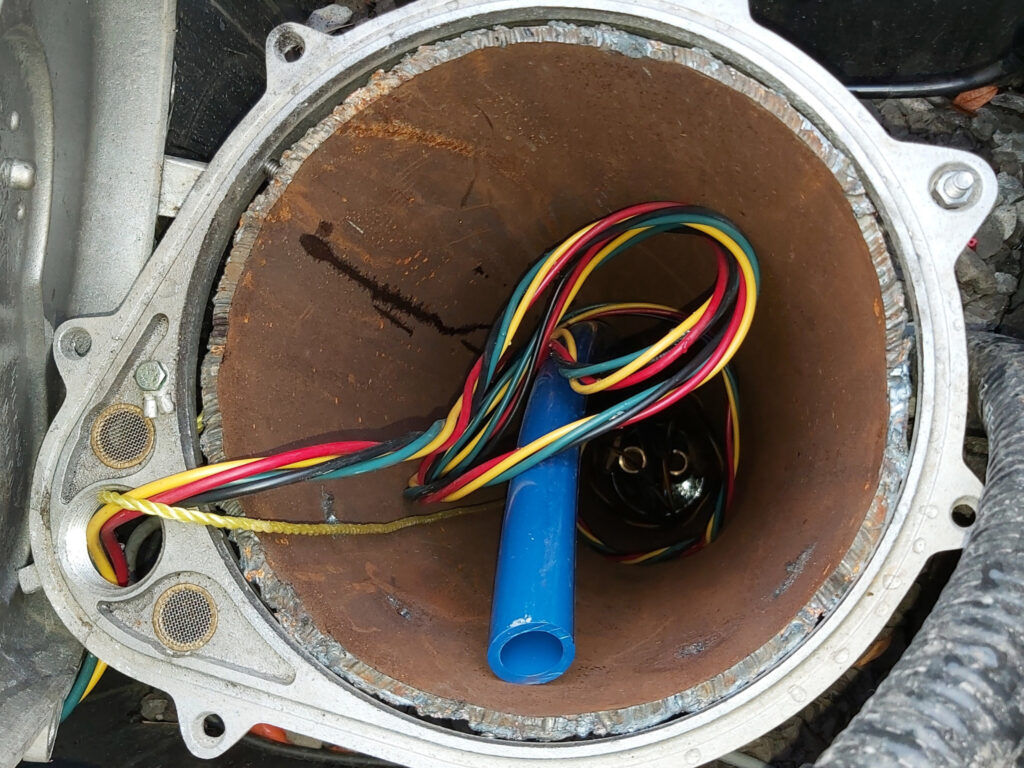

gbi’s mandate involved replacing the heating, ventilation, and air conditioning systems, followed by a reconfiguration of the mechanical room and the installation of a geothermal heat exchanger.

From the outset, in collaboration with the CSSMI, the idea of testing PCW geothermal technology was proposed, a newly adopted method in Quebec that is currently the subject of research by Polytechnique Montréal. The university selected gbi as its partner, following a public call for tenders, to test its theoretical model and demonstrate its viability in a real-world project.

PCW geothermal systems address Hydro-Québec’s main objective: reducing electricity demand during peak periods. This technology helps decarbonize buildings while meeting this challenge, and significantly reduces energy consumption in buildings, which account for 35% of all energy used in Quebec, as well as lowering energy bills for property owners.

Innovating with What Lies Beneath Our Feet

Permanent column wells (PCWs) are an innovative solution offering numerous advantages in this project.

This novel approach enables efficient heating and cooling of indoor environments by directly using groundwater, which transfers heat with the ground through conduction and advection. System performance can be significantly enhanced when the bleeding process is activated, a phenomenon where undisturbed groundwater infiltrates the well through natural fracture networks in the bedrock.

The major advantage of PCWs is the substantial reduction in the number of wells required compared to a closed-loop system. This makes it a viable option for confined spaces where geothermal energy was previously not considered feasible. This is particularly relevant for many existing buildings that will need to be decarbonized in the coming years.

% reduction in greenhouse gas emissions

% reduction in peak electricity demand

% reduction in energy consumption

Cost Reduction

Using a closed-loop geothermal system at Clé-des-Champs School would have required drilling 22 wells at a depth of 150 meters. Thanks to the use of permanent column wells (PCWs), only five 135-meter pumping wells and one injection well were needed, reducing the initial investment by 40 %.

Technically, PCWs allow for a longer water residence time in the well, which helps reduce peak electricity demand during extreme cold periods, easing the pressure on power generation and distribution infrastructure.

Meeting an Unmovable Deadline

One of the main challenges was meeting an immovable deadline: the school calendar. The project had to begin as soon as classes ended, and the schoolyard, with its new wells, had to be ready two months later. Most of the work was condensed into short timeframes over two phases.

Collaboration at the Core of the Project

gbi’s teams worked closely with Polytechnique Montréal to deploy an automatic control system capable of measuring and recording essential data to support ongoing university research.

This collaboration between research and real-world application drives progress and innovation in the geothermal sector.

Solutions to Every Complex Challenge

The project also stood out for the complexity of its exploratory phase, as extensive data was required to design the geothermal exchanger. In addition to a standard thermal response test, a pumping test and groundwater sampling were necessary.

The use of groundwater brings several challenges, such as managing suspended solids, clogging risks, and system durability. Our teams addressed these issues through multiple strategies : installing a filtration system, incorporating redundant plate heat exchangers to maintain continuous operation during maintenance, and using stainless steel to ensure the system’s longevity.

Despite the innovative nature of this project, I always felt you were in full control. Throughout the process, I truly appreciated your professionalism and the teamwork with all stakeholders, which allowed us to deliver an outstanding project.

Guillaume Marchand

Project Coordinator, Material Resources Department, CSSMI