Modular Multi-Residential Building – Le Cohab

Modular Multi-Residential Building – Le Cohab

2024

Canadian Consulting Engineering Awards

2024

Grands Prix du génie-conseil québécois

2024

Ordre des ingénieurs du Québec

2025

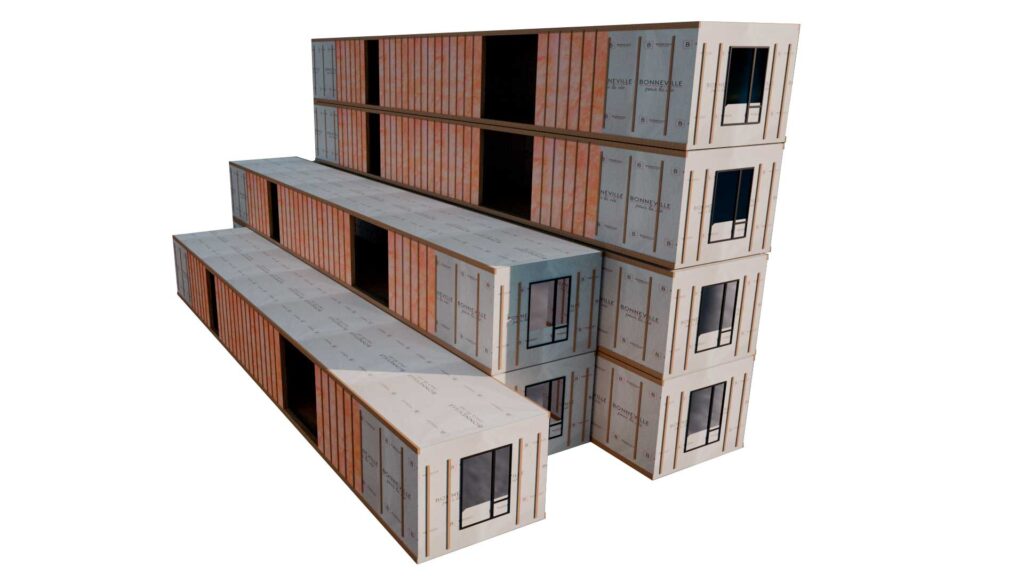

This 36-unit modular multi-residential building, featuring a wood structure, includes 24 units over four storeys assembled atop an underground parking garage. It serves as a pilot project for the client to showcase the performance of this type of construction while addressing the growing need for more affordable housing.

Structural, mechanical, electrical, and civil engineers from gbi worked together to ensure consistency and compatibility across every aspect of the project. This collaborative approach among all stakeholders was both different and more demanding, as the design plans had to be developed in parallel with the shop drawings, requiring an atypical schedule to meet the production start date set at the outset of the mandate. Coordination between the various stakeholders and engineering disciplines was crucial.

Moreover, despite differences between the modules and their unique calculation models, the integrated design process—driven by collaboration from all parties, made it possible to standardize the connections, enhancing both efficiency and safety on-site.

Technical Considerations for Assembly

The techniques for module-to-module and module-to-foundation assembly were a central focus of the project to ensure resistance to shear and overturning forces caused by wind and seismic activity.

The challenge of securing the modules to each other and to the foundations lay in the fact that some module faces were accessible only temporarily,until the next module was installed. The installation sequence was therefore a critical factor in the design, as it directly influenced the feasible assembly methods. Coordination of construction and installation sequences for a residential building is typically not, or only minimally, addressed at the design stage.

A staggered installation sequence was chosen, as it allowed maximum access to module faces for as long as possible during assembly. This solution, however, required special attention to ensure that the load path for wind and seismic lateral forces remained continuous from the roof down to the foundations. In a conventional building, lateral loads accumulate from the top to the bottom. In this case, to accommodate the installation sequence, an alternative load path was proposed, temporarily routing the loads upward by one floor before redirecting them downward. This allowed delivery of the modules with virtually no temporary openings inside the units for connecting them to one another.

days for assembly

material waste in the factory

waste container compared to 24 on a traditional construction site

A Design Addressing Social Challenges

This project offers a replicable model that addresses the housing shortage. The housing crisis is a major concern, and we are proposing a concrete solution for providing affordable housing within a shortened timeframe. Incorporating co-living units, apartments designed to meet the needs of remote work, and some reserved for foreign workers, this project delivers a diverse range of housing types within the same building.

Cost Savings

Significant savings at multiple levels were achieved through the optimal use of materials, reducing both material costs and the risk of budget overruns. The implementation of efficient processes, such as the use of a robotic saw to sort and cut wood pieces for optimal use, maximized material efficiency.

The optimization of material resources, such as using steel sheeting as both a firebreak and a structural connector, was made possible through the collaborative approach between structural, mechanical, and electrical engineers. By reusing components in multifunctional ways, we not only saved materials, time, and costs for the client, but also pushed the boundaries of what is traditionally considered in this type of construction.

Significant Schedule Reduction

Completed in just five weeks in the factory, four and a half days of on-site assembly, and only a few weeks of finishing wor, compared to a traditional project’s average nine-month timeline, this achievement reflects the innovation and vision of the gbi and Industries Bonneville teams from start to finish.

Each module was independently built in the factory with a high level of detail and finishing, then assembled on-site in record time. This approach reduced construction time by 50% compared to conventional methods, while ensuring unmatched quality and precision.

We are pleased with our collaboration with gbi, which allows us to test our new housing model. Addressing the housing crisis by standardizing a building while meeting a variety of needs is a source of pride for us. With gbi, we have a strong partnership that enables us to innovate and tackle housing challenges while focusing on efficiency and sustainability.

Gabrielle Bonneville

Senior Director, Real Estate and Construction